Current Sifton Camshaft information is available from http://www.crazyhorsespeedshop.com/

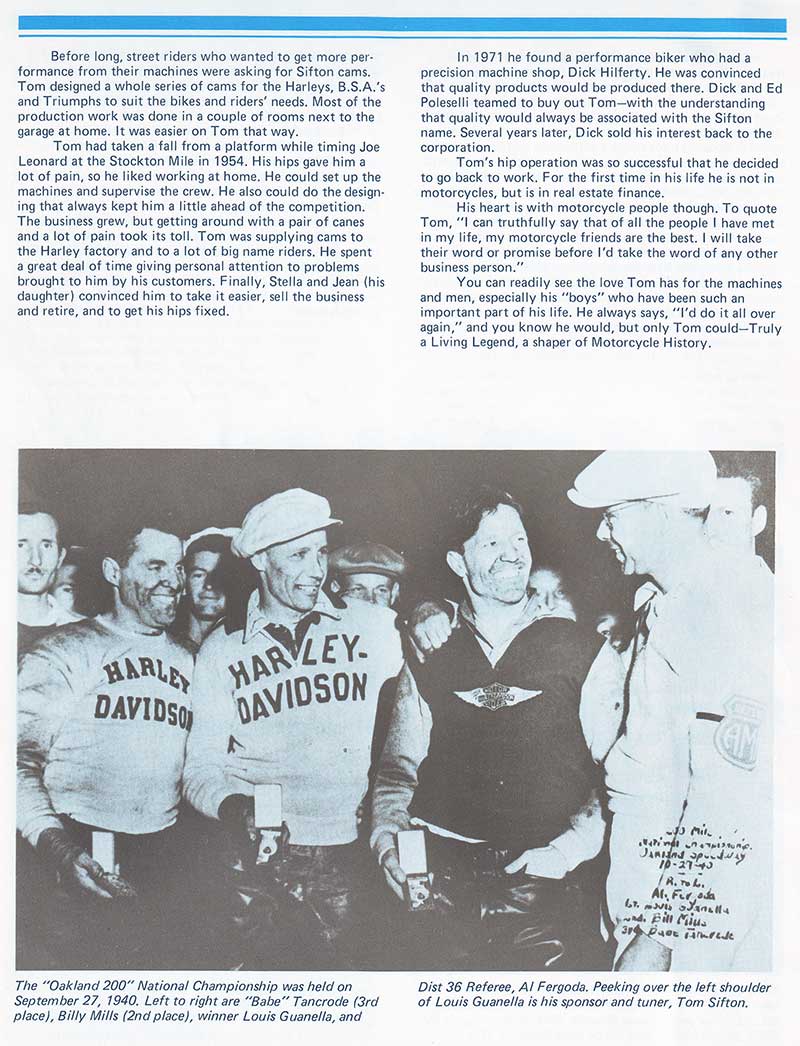

Sifton Dyno on display at Clovis Flat Track Museum

Tom’s Cam Grinder and Engine Dynamometer

Tom designed and built the Dyno & Cam Grinder on display. The dyno

is used to determind the engine horsepower and what is

unusual in that it uses a standard supercharger to load (or brake) the engine while running at high RPM - - - its an air brake,

where as commercially available dynamometer use electrical or hydraulic braking. The display is a mock-up only.

The operational setup would include all engine accessories & controls, e.g. tachometer, carburetor, throttle etc, etc.

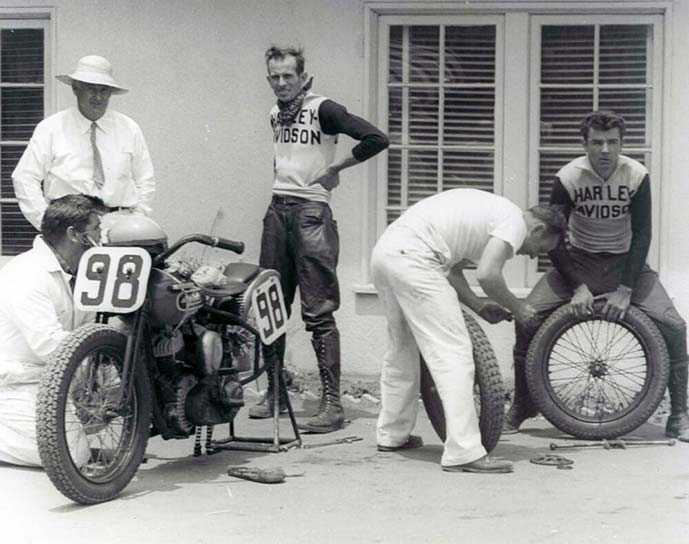

Tom used the dyno to develop the 500 cc BSA Gold Star ridden by Evertt Brashear @ the San Jose Mile as well as the 250 cc

Short Track engine on

display. Later a copy of this dyno develop the 85

Horsepower BSA Twin that Jim Rice raced at the

Sacramento Mile. Norman Smith 14y

https://magazine.cycleworld.com/article/2014/10/01/the-great-tom-sifton

|

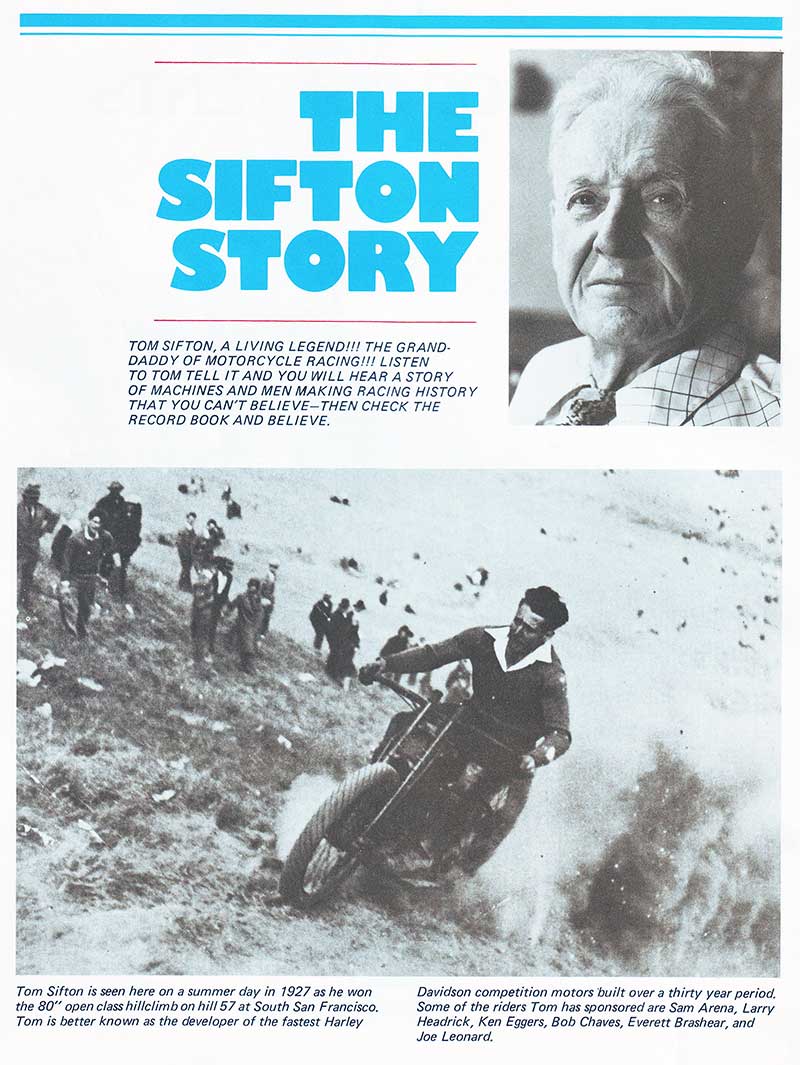

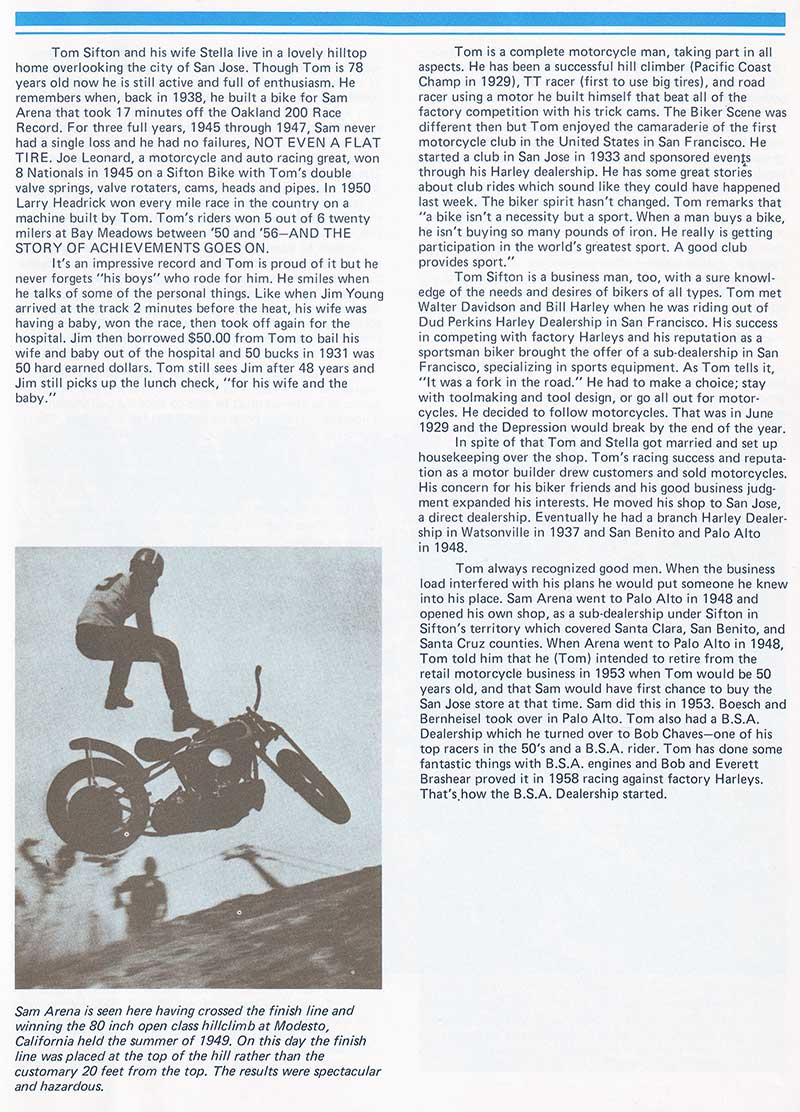

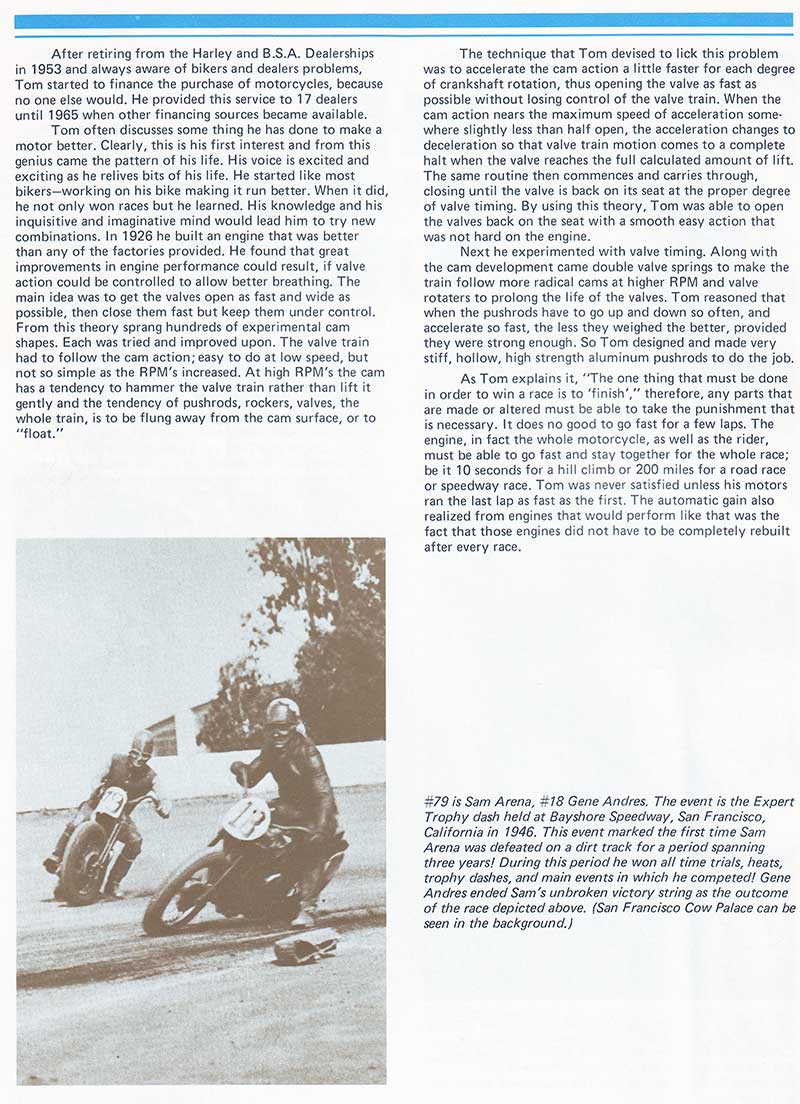

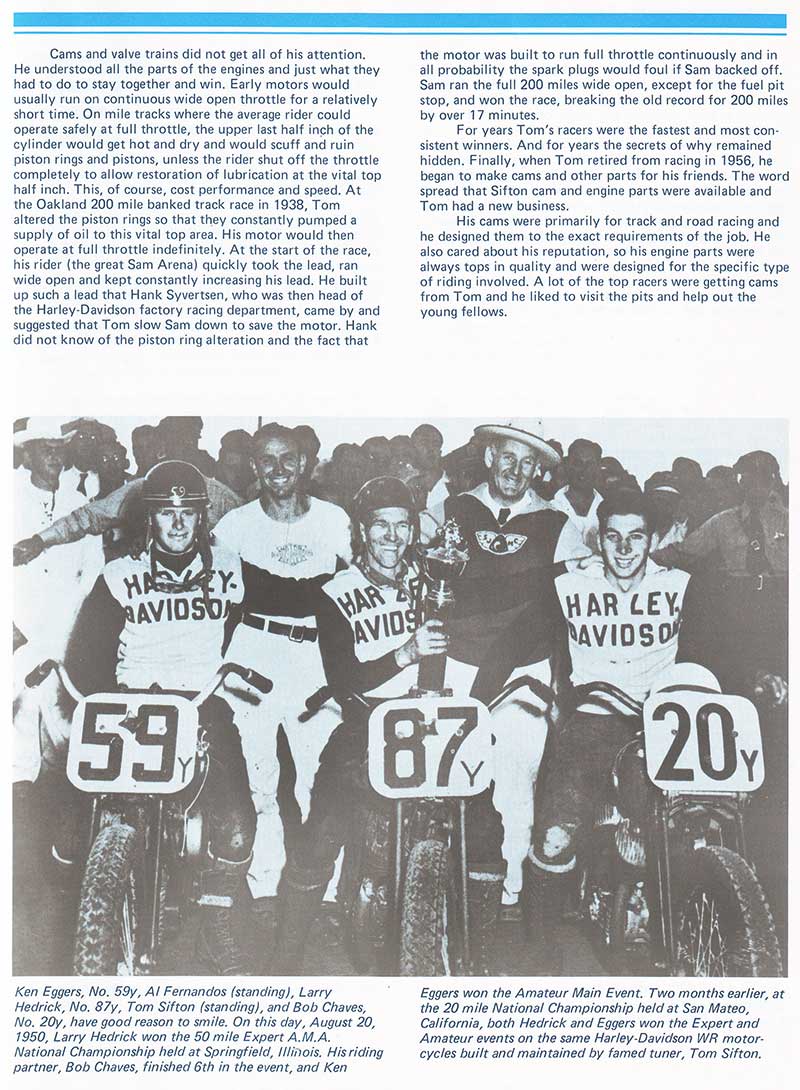

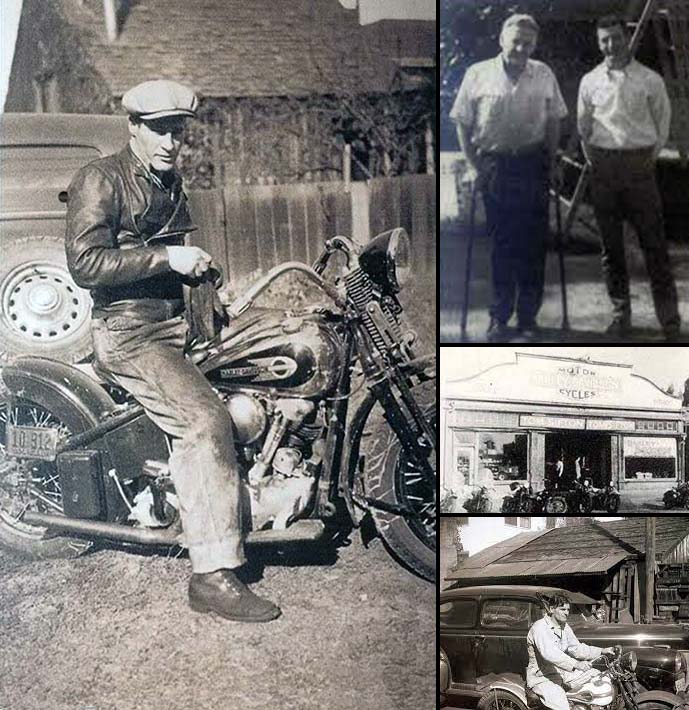

THE GREAT TOM SIFTON

A FOUNDING FATHER OF PERFORMANCE KEVIN CAMERON Cycle World October 1, 2014 Dirt-tracker/engineer Al Gunter put it into words when he told his protégé, Dick Mann, "Don't try to beat those guys using their ideas. They've had 'em a lot longer than you have. You need an edge, something nobody else has but you." He could very well have had Tom Sifton in mind. Sifton solved problems that other tuners just lived with, and he made the solutions win races. That was a long time ago. Sifton was a Harley dealer in the prewar days before Harleys even had recirculating oil systems, and it’s easy to dismiss the crude-looking, heavy bikes they tuned and rode as irrelevant and boring. Now think of how crude our “sophisticated” bikes of today will look in 80 years. What is most interesting in all eras is how people understood and solved the problems they faced. In 1937, Harley gave its W-series engines a full dry-sump oil system. With the two pistons of a 45-degree V-twin rising and falling almost together, how do you collect oil and pump it back to the external tank? Oil scraper rings were just coming into use, so it was best to have a timed crankcase breather valve that would pump the case negative most of the time, discouraging oil from moving up past the rings to the combustion chamber, where limited ignitions and 0.014-inch plug gaps made fouling easy. Keep that oil out! These were side-valve engines— “flatheads” in the old terminology. Beside each cylinder was a pair of valves, stems down. Intake air flowed up to each intake valve then across a short shelf to the top of the cylinder, where the flow turned down across the cylinder edge at 90 degrees. Lots of inefficient twisting and turning. Everything was very hot in racing because these cylinders and their valve ports were cast iron. Iron is a great friction surface, and it’s hard enough to act as a valve seat, but it transmits heat poorly. Over at Excelsior, Arthur Lemon had made a step forward in 1921 by providing an air space between the cylinder and the very hot exhaust port, reducing bore distortion. Power-mower engines use Lemon’s idea to this day. Racing these engines pushed cylinder wall temperatures high enough to vaporize the thin oil film, leading to scoring of rings and pistons. Air-cooled aircraft engines faced the same; a piston ring could wear to half its original thickness in 30 hours. As described in Jerry Hatfield’s book American Racing Motorcycles, the accepted way to cope was to close the throttle in the turns of dirt-track races, creating a vacuum that drew oil up past the pistons to wet the cylinder walls, preventing scoring. Sifton thought beyond that, finding a combination of breather timing and piston-ring shape that kept cylinder walls oily without throttle closure yet did not throw enough oil to foul the plugs. With his throttle open more of the time, rider Sam Arena in 1938 won a 200-mile Oakland, California, Class-C race, shattering the old record by 19 minutes and 20 seconds. Talk about having an edge. As engines revved higher, their valves floated. Sifton thought about the details. If less time were used to accelerate the valve upward, that would make more time available in which the spring could slow and reverse the valve’s motion. This allowed higher revs—and more power— without valve float. Another edge. Exhaust valves ran hotter on the cylinder side (where there was no access for cooling air). This caused part of the valve to expand more, distort, leak, and then break. Sifton added roto-caps to his valve train, rotating the exhaust valves 6 degrees with each lift. Temps equalized, and failure was postponed. BY THE NUMBERS 1968 YEAR THAT SIFTON'S RIDER, JOE LEONARD, QUALIFIED ON THE POLE FOR THE INDY 500. HIS LOTUS WAS POWERED BY A PRATT & WHITNEY TURBINE. 2:22.38 SAM ARENA'S RECORD SETTING TIME IN THE 19~8 200-MILE PACIFIC COAST SPEEDWAY CHAMPIONSHIP IN OAKLAND, CALIFORNIA. 84.13 ARENA'S WINNING AVERAGE SPEED IN MPH. REMEMBER, THIS WAS 1938. Big problems in flatheads were cylinder distortion and the related need to make pistons in the shape the cylinder would take when hot. Sifton pioneered cylinder finishing with head-bolt torque in place and the pre-shaping of pistons to prevent hot seizure. When cast-iron piston rings fell behind, Sifton did what world aviation did in 1940: He adopted a hard-chrome-plated top piston ring. Did he borrow this from aircraft engines or diesels? Doesn’t matter. He knew it worked and used it to stop failure. From experience, he knew bigger-than-stock intake valves did nothing for his Harley engines. Instead of just accepting that, he made a cast of his engine’s combustion chamber then sectioned it in several places and directly measured the flow area it provided between valve and cylinder. Sure enough, the choke point was not the valve. It was the height of the flow path from valve region to cylinder. Lowering the floor provided the needed flow area, and blending the floor down into the cylinder smoothed it. Another edge: 4 more horsepower. It’s so easy in racing to think power comes from hot tips. Use this oil. File that edge. But no, it comes from thinking clearly about what stands between your engine and making greater power, between your chassis and stronger drives. Find and define the problem then solve it. Tom Sifton in effect built his own Spintron—a rig illuminated by strobe light in which the entire valve train could be run at speed and its detailed action observed in slow motion. When flat tappets scored or broke under higher spring loads, he adopted roller tappets. Sifton’s method for design of cam profiles became the basis of a cam business. In 1954, Sifton delegated management of his dealership to concentrate on racing. His rider, Joe Leonard, won eight nationals that year. Engines showed Sifton what they needed, and he provided it. Were piston rings sticking or pistons cracking? Was the old trouble of ring and piston scoring back? I wish I knew more. But whatever the cause, his answer was to create something few had then imagined: pistoncooling oil jets of the kind now becoming universal on sportbike engines. Did he take the idea from aircraft piston engines? Again, doesn’t matter. He had an answer. When critics asserted it was easy for big 750 flatheads to beat 500CC overhead valve engines, he built a race-winning ohv 500. Clear cause-and-effect thinking doesn’t have a brand name or a displacement. |